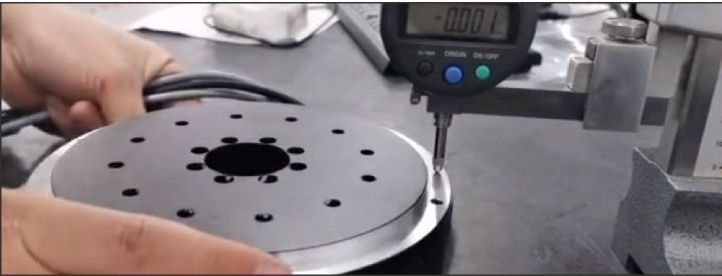

严格的过程控制,先进的生产设备,一丝不苟的工作态度,完善的管理体系,使我们的产品逐步迈向零缺陷目标迈进

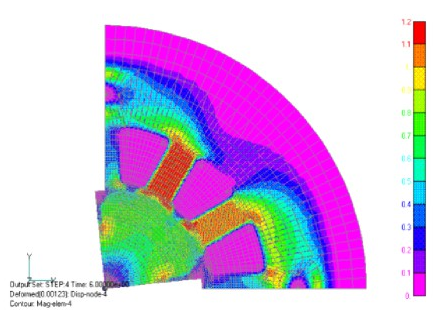

精密的电磁仿真设计

保证最佳的磁极比

合理的硅钢片齿形

智和与中国科学院材料所团队合作,设计的电机推力密度比市场同类产品高30%~40%,使客户提高产能,同时降低成本。

Precision electromagnetic simulation design

Ensure optimal magnetic pole ratio

Reasonable tooth shape of silicon steel sheet

Zhihe cooperated with the Materials Institute of the Chinese Academy of Sciences, and the designed motor thrust density was 30%~40% higher than that of similar products in the market, which enabled customers to increase production capacity and reduce costs.

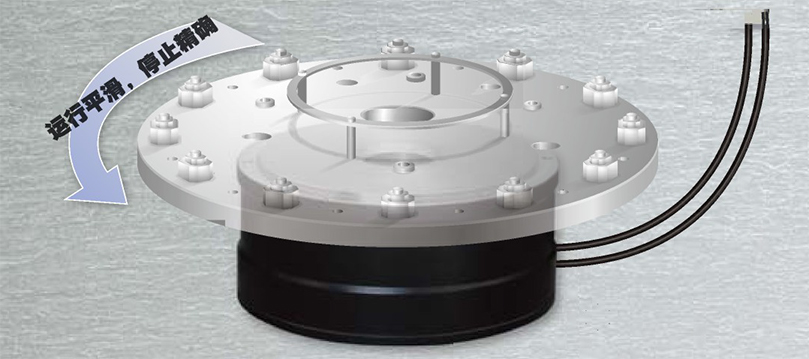

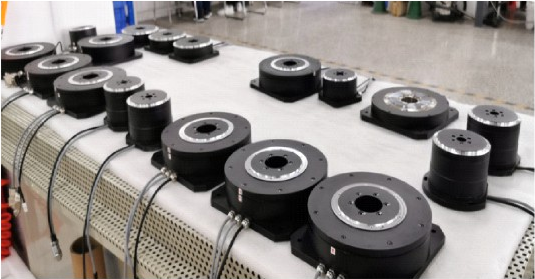

目前开发的DD马达超过100个规格

转子类型:内转子,外转子

直径:60mm-708mm

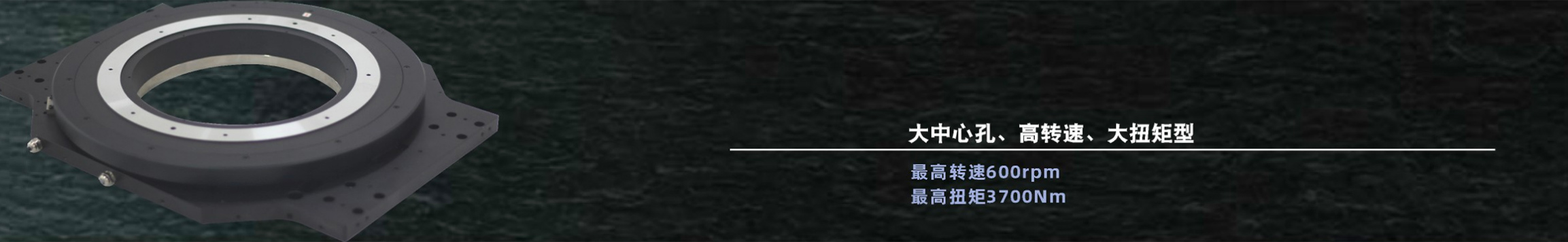

扭矩:1Nm-3000Nm

Currently developing over 100 specifications of DD motors

Rotor type: inner rotor, outer rotor

Diameter: 60mm-708mm

Torque: 1Nm -3000Nm

Evolving World of Motion Dynamics

节能、发热量低

能承受突变的外力

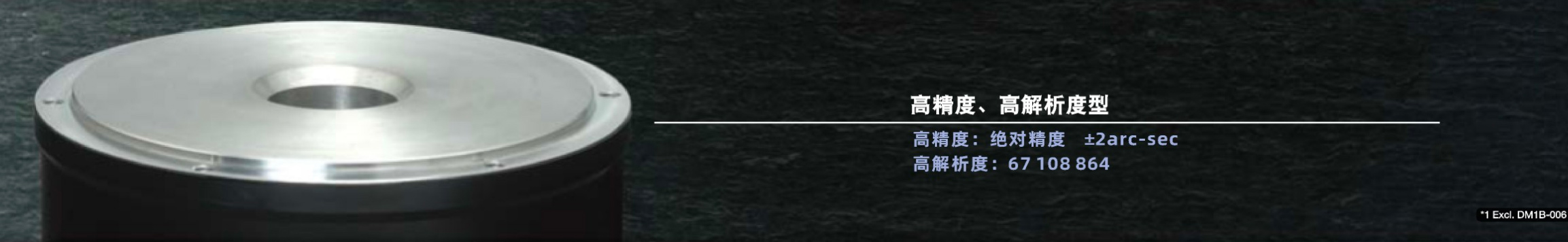

重复定位精度+0.5arc sec,绝对定位精度+ 2 arc sec 67108,864脉冲/转相当于在1000mm的长臂未端具有0.5um的精度

能承受突变的外力

混合磁路使用偏磁的方法,在低电流下产生高扭矩。从而减少发热并且节能

L-PD控制提供了高刚性。这使得智和DDR可以承受突变的外力